NSN 5306-01-195-1602 BACB30NF552D, BACB30NF5-52D, BACB30NF5D52

Product Details | CLOSE TOLERANCE BOLT

5306-01-195-1602 An externally threaded fastener whose unthreaded portion is of a specified grip length, plated or unplated, and is machined to a tolerance of one thousandth (0.001) of an inch (0.025 mm) or less of a specific diameter for items one inch (25 mm) or less in diameter. Items over one inch (25 mm) in diameter shall have a tolerance of fifteen ten-thousandths (0.0015) of an inch (0.038 mm) or less. The nominal major diameter of the threads shall be at least one thousandth (0.001) of an inch (0.025 mm) below the minimum shank diameter, but not below the minimum major diameter for applicable class of fit, as shown in the Screw Thread Standards, FED STD H28 and/or other nationally recognized standards. The head is not designed to be held or driven with an inserted driver, nor is it designed for rotation by the thumb and fingers. A locking feature may be incorporated in the design of the head or threads. For items having close tolerance, and fabricated from material having 160,000 pounds per square inch (1100 megapascals) minimum tensile strength, see BOLT, SHEAR. For items fabricated from material having less than 160,000 pounds per square inch (1100 megapascals) minimum tensile strength and not having a close tolerance, see BOLT, MACHINE.

Part Alternates: BACB30NF552D, BACB30NF5-52D, BACB30NF5D52, 5306-01-195-1602, 01-195-1602, 5306011951602, 011951602

Hardware and Abrasives | Bolts

| Supply Group (FSG) | NSN Assign. | NIIN | Item Name Code (INC) |

|---|---|---|---|

| 53 | 01-195-1602 | 27851 ( BOLT, CLOSE TOLERANCE ) |

Request a Quote

What Our Customers Say

Compare

Related Products | NSN 5306-01-195-1602

Technical Data | NSN 5306-01-195-1602

| Characteristic | Specifications |

|---|---|

| THREAD SERIES DESIGNATOR | UNJF |

| NOMINAL THREAD DIAMETER | 0.312 INCHES |

| THREAD QUANTITY PER INCH | 24 |

| THREAD CLASS | 3A |

| THREAD DIRECTION | RIGHT-HAND |

| THREAD LENGTH | 0.429 INCHES MINIMUM AND 0.479 INCHES MAXIMUM |

| FASTENER LENGTH | 3.689 INCHES MINIMUM AND 3.719 INCHES MAXIMUM |

| MATERIAL | STEEL COMP E4340 OR STEEL COMP 8740 OVERALL |

| MATERIAL DOCUMENT AND CLASSIFICATION | MIL-S-5000 MIL SPEC 1ST MATERIAL RESPONSE OR MIL-S-6049 MIL SPEC 2ND MATERIAL RESPONSE OR AMS6322 ASSN STD 2ND MATERIAL RESPONSE OVERALL |

| SURFACE TREATMENT | CADMIUM AND CHROMATE OVERALL |

| SURFACE TREATMENT DOCUMENT AND CLASSIFICATION | QQ-P-416,TY2 CL 2 FED SPEC SINGLE TREATMENT RESPONSE OVERALL |

| MINIMUM TENSILE STRENGTH | 140000 POUNDS PER SQUARE INCH |

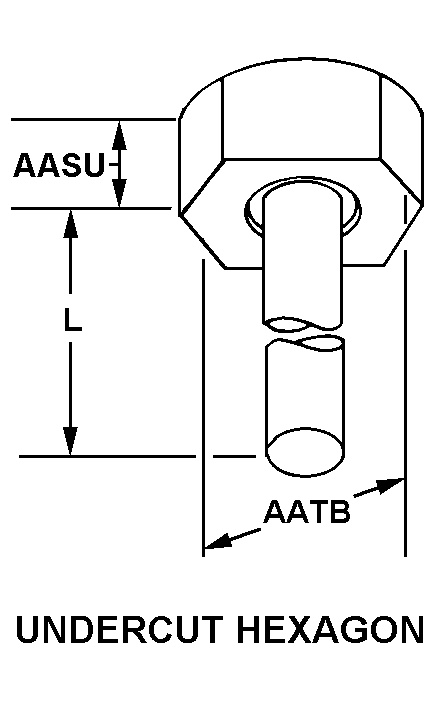

| HEAD STYLE | C2 UNDERCUT HEXAGON |

| HEAD HEIGHT | 0.156 INCHES MINIMUM AND 0.171 INCHES MAXIMUM |

| WIDTH BETWEEN FLATS | 0.492 INCHES MINIMUM AND 0.502 INCHES MAXIMUM |

| GRIP LENGTH | 3.240 INCHES MINIMUM AND 3.260 INCHES MAXIMUM |

| GRIP DIAMETER | 0.3110 INCHES MINIMUM AND 0.3120 INCHES MAXIMUM |

| SURFACE FINISH | 32.0 MICROINCHES BEARING SURFACE OF HEAD 32.0 MICROINCHES GRIP 32.0 MICROINCHES THREADS |

| DISTANCE FROM HEAD LARGEST BEARING SURFACE TO SHANK HOLE CENTER | 3.304 INCHES MINIMUM AND 3.554 INCHES MAXIMUM FIRST HOLE |

| SHANK UNTHREADED HOLE DIAMETER | 0.076 INCHES MINIMUM AND 0.086 INCHES MAXIMUM FIRST HOLE |

Restrictions/Controls & Freight Information | NSN 5306-01-195-1602

| Category | Code | Description |

|---|---|---|

| Hazardous Material Indicator Code | N | There is no data in the HMIS and the NSN is in an FSC not generally suspected of containing hazardous materials |

| Electro-static Discharge Susceptible: | A | No known Electrostatic Discharge (ESD) or Electromagnetic Interference (EMI) sensitivity |

| Category | Code | Description |

|---|---|---|

| No Freight Information | ||